PRODUCTION

︎︎Yaha-Yahui - Organic Mezcal is produced within the artesanal tradition - all made by hand without the help of modern machinery and 100% natural.

Harvest

The maguey (agave) is a unique plant. It only blooms once in its lifetime and it may take decades (up to 35 years) of growth to come to this state. The magueys need to be cut just before blooming as that is the time when the piña (the heart) reaches its highest sugar level. At this point, the piñas are very heavy. In our first batch, we saw piñas weighing more than 340kg.

The harvest itself requires lots of manpower and in our case the help of a horse to carry these heavy plants from the place of harvest to the palenque, where the actual Mezcal production is taking place.

The harvest itself requires lots of manpower and in our case the help of a horse to carry these heavy plants from the place of harvest to the palenque, where the actual Mezcal production is taking place.

Roasting

In order to be able to unfold the sugars within the magueyes, the piñas need to be cooked. For artesanal Mezcal this is done in a traditional earth oven pit. The Maestros Mezcaleros start a fire in the bottom of the pit and cover it gently with stones, which protects the magueys from being burnt. Then the harvested agaves are layered on top of the stones, which are then covered with petates (mats made from palm leaves) and soil. For our Batch No. 1 - Yaha-Yahui the magueys were cooked for 3 days.

Roasting is crucial - as in this stage some of the deepest aromas such as the Mezcal’s distinct smokiness are developed.

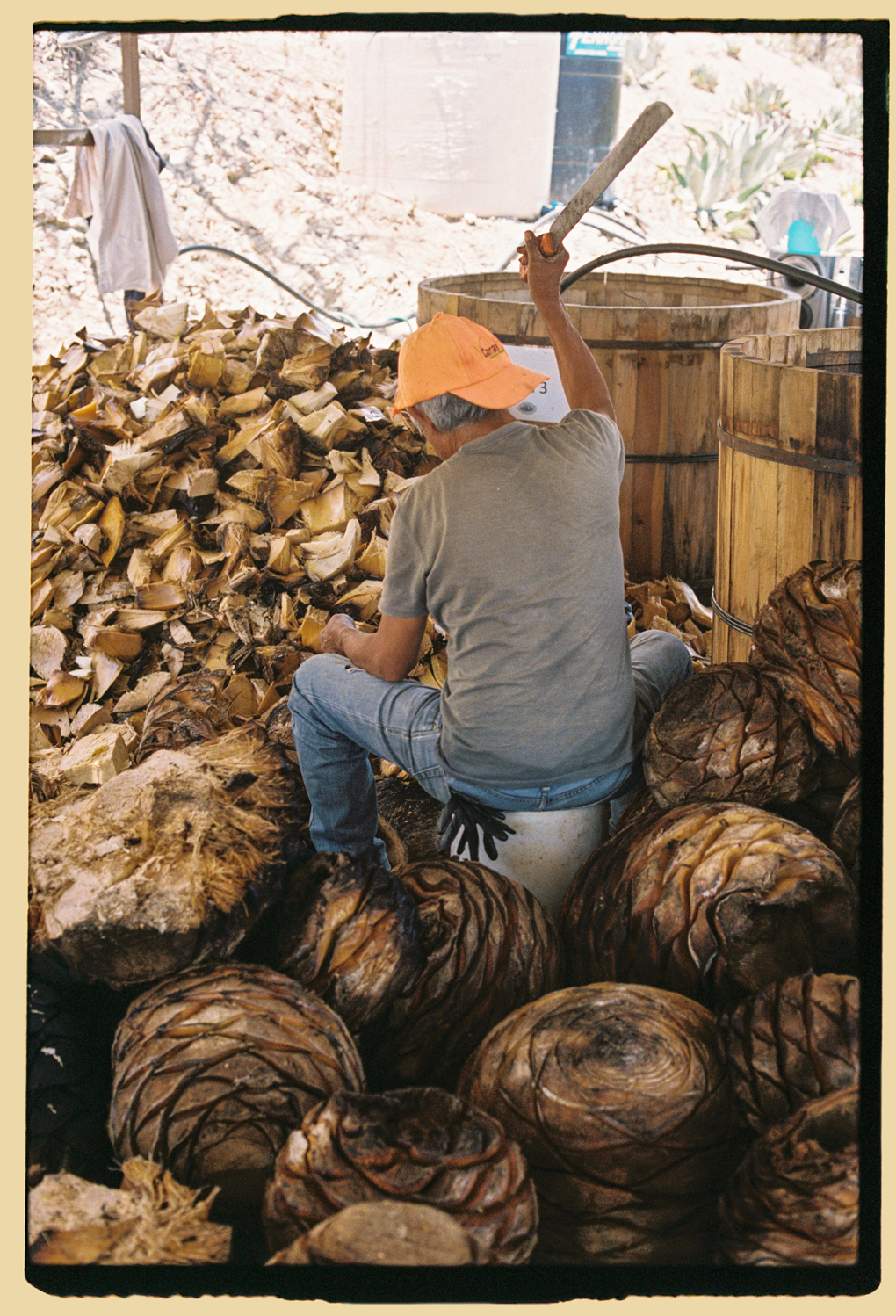

Shredding & Milling

After the roasting, the piñas need to be shredded. First, the cooked agave hearts are cut into small pieces by hand, using axes and machetes. After that, the pieces of agave are milled with a giant stone wheel, called a tahona, which is turned by our Maestros horse Apocalypto.

The milling is a very labor-intensive and tiresome work that takes up to 2 days.

The milling is a very labor-intensive and tiresome work that takes up to 2 days.

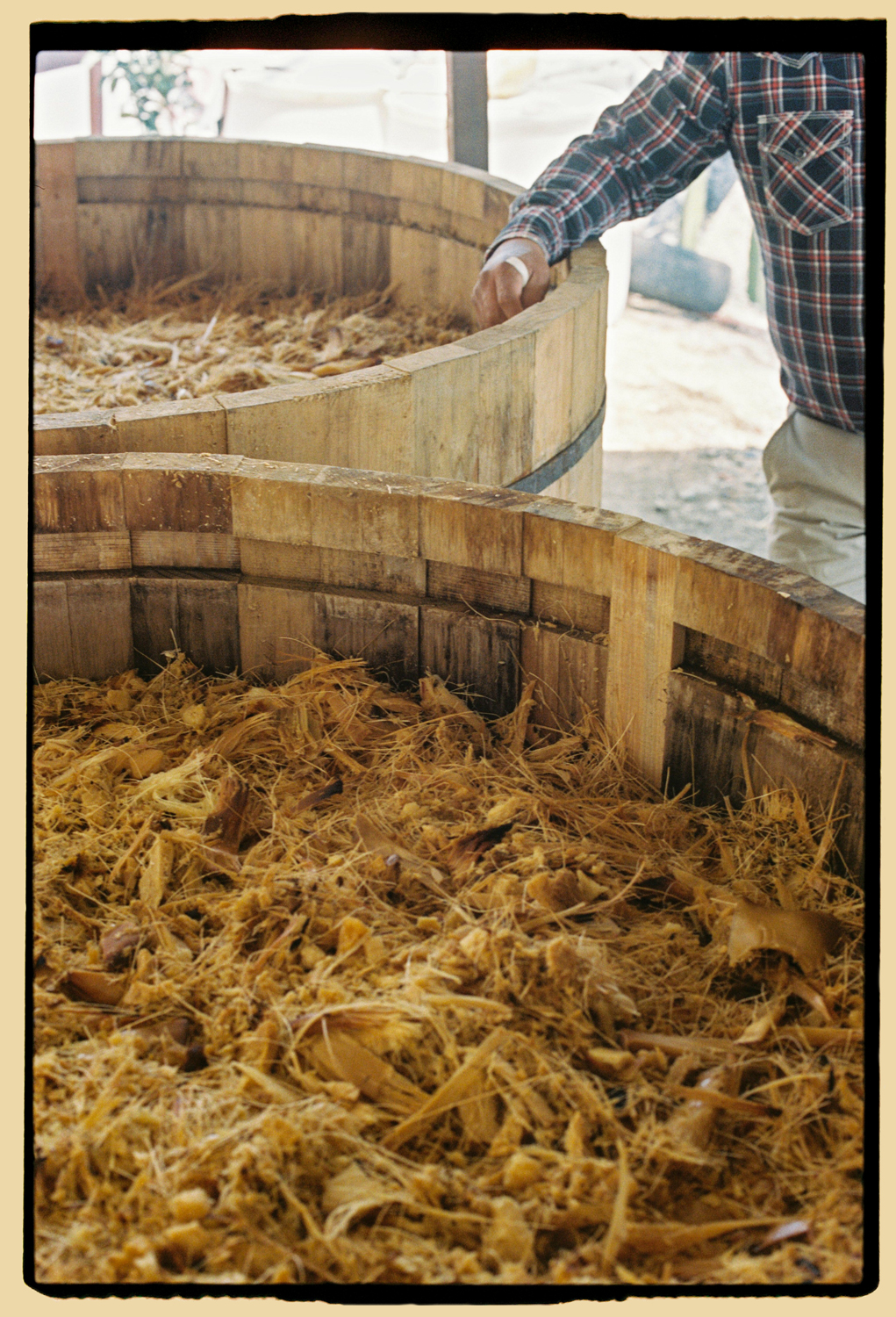

Fermentation

The most decisive part of the production process is the fermentation of the agave fibers, where the sugars are turned into alcohol.

During this step, all the flavors of the Mezcal are developed and finalized. The fibers and water are placed in large, open wooden barrels and left to ferment fully naturally with indigenous and wild yeast for 8 to 16 days - a timespan that is significantly longer than in the conventional production of fermented alcoholic beverages.

Finding the right moment to end the fermentation process is crucial. If the fibers are fermented for too long the flavors and depth of aromas change and will reduce the quality of the final product. Hence, during this stage of production, the Maestros Mezcaleros and their team need to be ready day and night to be able to quickly start the distillation process.

During this step, all the flavors of the Mezcal are developed and finalized. The fibers and water are placed in large, open wooden barrels and left to ferment fully naturally with indigenous and wild yeast for 8 to 16 days - a timespan that is significantly longer than in the conventional production of fermented alcoholic beverages.

Finding the right moment to end the fermentation process is crucial. If the fibers are fermented for too long the flavors and depth of aromas change and will reduce the quality of the final product. Hence, during this stage of production, the Maestros Mezcaleros and their team need to be ready day and night to be able to quickly start the distillation process.

Distillation

The last stage of the production process is the distillation itself. Here the mash (the fermented agave fibers and the fermentation liquid) is distilled using an alembic copper still. This process requires the Maestros Mezcaleros a rich skillset and in-depth knowledge.

First, the separation of the distillation product - meaning cutting off the puntas (head) and colas (tail) from the Mezcal - will define the quality, bouquet, and taste profile of the spirit. Knowing when to cut-off and is depending on expertise and feeling.

Secondly, to be able to cut the puntas and colas properly, steady temperatures are needed. Since, in the artesanal production method, wood fire is used to heat up the still, creating a stable production environment is very challenging.

In order to achieve a clean and high-quality spirit, our Mezcal is distilled twice.

First, the separation of the distillation product - meaning cutting off the puntas (head) and colas (tail) from the Mezcal - will define the quality, bouquet, and taste profile of the spirit. Knowing when to cut-off and is depending on expertise and feeling.

Secondly, to be able to cut the puntas and colas properly, steady temperatures are needed. Since, in the artesanal production method, wood fire is used to heat up the still, creating a stable production environment is very challenging.

In order to achieve a clean and high-quality spirit, our Mezcal is distilled twice.